The 5 Biggest Challenges Electrical Contractors Face

– And How SES Helps Solve Them –

How good would it be to complete a job on time, under budget, the security of local support and service, backed by huge warranty periods?

You’d be a hero, right?

How much money is your company losing by not delivering projects on time, because you’ve been screwed by ridiculous lead times on product, shipping delays, or inadequate supplier service and documentation?

Heaps, right?

Electrical contractors and industrial clients face a range of challenges on every project. From material delays to compliance headaches, these issues can slow down progress, increase costs, and impact overall profitability.

Key Pinch Points

- Project Timelines & Delays

- Tight / unrealistic Budgets

- Equipment Reliabilty

- Standards & Regulations

- Unreliable Suppliers

At SES Transformers, we understand these challenges – because we work with contractors every day. Our goal is to provide reliable, high-quality transformers with fast turnaround times, helping projects stay on time, on budget, and compliant with Australian standards.

SES will help you deliver your project on time.

Here are the top five challenges that electrical contractors deal with – and how SES helps solve them.

1. Project Delays Due to Material Supply Issues

The Challenge:

One of the biggest frustrations on any job is waiting for materials to arrive.

Long lead times on transformers, switchgear, cabling, and other electrical equipment can cause significant project delays.

Overseas suppliers often promise quick delivery but fail to meet deadlines due to shipping hold-ups, customs delays, or supply chain disruptions.

Labour scheduling becomes difficult when key materials aren’t available, leading to increased costs and inefficiencies.

How SES Helps:

✅ Australian-Made Transformers – No international shipping delays or import hassles.

✅ Shorter Lead Times – We manufacture everything locally, ensuring faster delivery.

✅ Stock Availability – Common transformer designs are available off the shelf for urgent needs.

✅ Rapid Customization – Need something specific? Our in-house team can deliver custom solutions without long delays.

By providing fast and reliable supply, SES helps contractors keep projects on schedule and avoid costly downtime.

2. Meeting Australian Standards & Compliance Requirements

The Challenge:

Electrical contractors must ensure that all materials and installations comply with Australian electrical regulations (AS/NZS standards).

Cheap imported transformers often fail compliance checks, leading to rejected inspections, rework, and fines.

Increasing regulations mean more testing, certification, and documentation requirements.

How SES Helps:

✅ AS/NZS-Compliant Transformers – Fully tested to meet Australian regulations.

✅ Certified In-House Testing – Every transformer is rigorously inspected before leaving our facility.

✅ Technical Documentation Provided – Making compliance easier for contractors.

With SES, contractors can be confident in passing inspections the first time, avoiding costly delays and rework.

3. Ensuring Equipment is Reliable & Built to Last

The Challenge:

Unreliable electrical equipment leads to failures, project downtime, and increased maintenance costs.

Harsh industrial environments (heat, dust, moisture) can cause premature breakdowns.

Low-quality transformers and electrical components result in higher failure rates and safety risks.

How SES Helps:

✅ Built for Harsh Conditions – Our transformers are designed for industrial, mining, and commercial applications.

✅ Dry-Type Transformers – Lower Maintenance & Fire Risk – No oil, making them safer and easier to maintain.

✅ High-Quality Materials – We use premium-grade copper or aluminium windings, high-efficiency cores, and durable enclosures.

By choosing SES transformers, contractors get longer-lasting, more reliable solutions that reduce maintenance costs and project downtime.

4. Managing Tight Budgets & Cost Pressures

The Challenge:

Electrical contractors need to balance quality with cost.

Some projects prioritise low-cost imports, but these often result in higher lifetime costs due to failures and inefficiencies.

Unexpected costs from project delays, rework, or unreliable equipment can eat into profits.

How SES Helps:

✅ Competitive Pricing – We offer high-quality transformers at cost-effective rates.

✅ Lower Lifetime Costs – Reliable transformers mean less maintenance and fewer failures.

✅ Faster ROI – With quicker installation and fewer issues, contractors can complete jobs faster and get paid sooner.

Choosing SES means contractors save money in the long run, with fewer headaches and lower overall costs.

5. Dealing with Unreliable Suppliers & Poor Support

The Challenge:

Many suppliers don’t prioritise customer service, leaving contractors to deal with:

Slow response times and lack of communication.

Limited customisation options, forcing contractors to modify products on-site.

No technical support when issues arise.

How SES Helps:

✅ Direct Access to Our Engineering Team – Get expert advice and support when you need it.

✅ Fast Response to Issues – We work directly with contractors to solve problems quickly.

✅ Custom-Built Solutions – If you need a specific transformer design, we’ll build it to your exact specifications.

With SES, you get a supplier who actually supports your business, ensuring smoother projects and better outcomes.

Why Contractors Choose SES Transformers

At Southern Electronic Services (SES), we understand the challenges contractors face – and we build solutions to help overcome them.

✅ Fast, reliable transformer supply – Made in Australia, with shorter lead times.

✅ Compliant with AS/NZS standards – Fully tested and certified.

✅ Built for reliability – High-quality materials, low maintenance, and long lifespan.

✅ Cost-effective solutions – Competitive pricing without cutting corners.

✅ Excellent customer support – Direct access to our engineers and fast response times.

By choosing SES, contractors can complete projects faster, avoid costly rework, and ensure long-term reliability for their electrical installations.

Need a Reliable Transformer Supplier?

If you’re looking for high-quality, Australian-made LV dry-type transformers, SES is here to help.

📞 Call us today to discuss your next project.

Next Post

Temperature rise and Transformer Life

March 12, 2025Other News

Isolation or auto transformer… Which is right for you?

5 Tips to Determine Whether You Need an Isolation Transformer or an Autotransformer Choosing the right transformer for your electrical system is crucial for efficiency, safety, and compliance. Many electricians and engineers often ask: When should I use an isolation transformer, and when is an autotransformer the right choice? To help you make an informed…

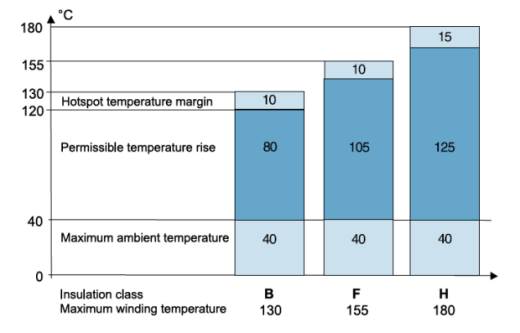

Temperature rise and Transformer Life

The Impact of Temperature Rise on Transformer Life Expectancy Temperature is one of the most critical factors affecting the lifespan of a transformer. Many in the industry are familiar with the well-established rule: For every 10°C reduction in operating temperature, a transformer’s life expectancy doubles. Equally, for every 10°C hotter a transformer runs, the life…